Innovative Approaches to Precision Concrete Cutting: Trends, Techniques, and Safety

The Modern Landscape of Concrete Cutting

Concrete cutting has evolved significantly, reflecting advancements in construction methods and the increasing demand for accuracy. Traditional tools like saws and drills remain essential, but modern projects rely on diamond-tipped blades, wire sawing, and robotic equipment to achieve cleaner cuts with minimal disruption. These approaches improve efficiency and reduce structural damage and downtime, making them essential in today’s fast-paced building and renovation environments.

Equally important is the focus on safety and sustainability. Dust control systems, noise reduction techniques, and remote-operated machinery protect workers while ensuring compliance with environmental standards. The industry continues to adapt with technology-driven solutions that balance precision, safety, and efficiency. More info on innovative approaches to precision concrete cutting is available for those interested in learning about evolving trends, equipment, and field best practices. These innovations highlight how construction practices continue to advance while meeting modern demands.

Key Techniques Used in Precision Sawing

Modern precision concrete cutting comprises an array of specialized techniques, each tailored to specific construction and demolition requirements. The most widely used methods include:

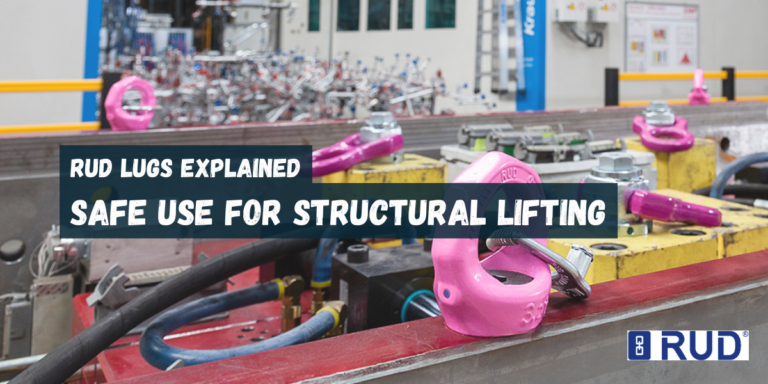

- Diamond Wire Sawing: Renowned for its versatility and effectiveness, this technique employs a wire embedded with diamond beads to slice through concrete and steel, delivering clean edges with minimal vibration.

- Wall Sawing: Utilizing circular diamond blades mounted on a track, wall saws excel at creating doorways, windows, and openings in vertical or steeply inclined surfaces while ensuring accurate dimensioning.

- Flat Sawing: Sometimes called slab sawing, is vital for cutting roads, pavements, and foundation slabs. It produces smooth surfaces and minimizes structural disturbance.

The optimal cutting approach depends on project size, structural complexity, access restrictions, and noise or dust limitations—making a deep understanding of available technologies crucial for project success.

Advantages of Diamond Wire Sawing

Diamond wire sawing stands at the forefront of modern concrete cutting thanks to its extraordinary versatility and low environmental impact. Compared to traditional methods, it reduces vibration and noise, safeguarding adjacent structures from microcracking and collateral damage. Capable of navigating confined or underwater spaces, diamond wire saws make it possible to tackle projects previously considered unmanageable. The method also improves workplace safety by minimizing airborne dust and supporting remote operation—key benefits in controlled demolition and restoration. These advantages are primary reasons this technique is increasingly favored for infrastructure upgrades, industrial modifications, and specialty construction projects.

Applications of Precision Concrete Cutting

Precision concrete cutting underpins a broad spectrum of construction, retrofit, and demolition tasks. It is routinely used to carve new doors, windows, and mechanical openings in pre-existing walls without compromising structural integrity. Slabs, columns, and beams can be selectively removed to accommodate new designs or upgrades, while roads and bridges undergo precise modifications for utility installations or repairs. This adaptability extends to high-stakes projects such as safe bridges and infrastructure demolition and specialty jobs that demand tight tolerances and minimal disruption.

See also: How to Develop Your Prompt Engineering Skills for Technical Tasks

Safety Measures and Industry Best Practices

Progressive safety standards now govern every aspect of concrete cutting, emphasizing hazard reduction through equipment checks, skilled operator training, and comprehensive personal protective equipment (PPE) use. Silica dust—one of the most significant risks—necessitates robust dust suppression systems and thorough site ventilation. The Occupational Safety and Health Administration (OSHA) provides essential guidelines to ensure employers monitor air quality and implement adequate controls, protecting workers and improving productivity. By rigorously applying these protocols, companies lower risks and foster a culture of ongoing safety improvement.

Emerging Technologies Shaping the Industry

Innovations in robotics, automation, and data-driven monitoring redefine what is possible within concrete cutting. Remote-controlled saws and semi-autonomous systems are reducing manual labor, ensuring greater consistency, and widening access to hazardous or hard-to-reach environments. Sensor-driven technologies allow for real-time observation of dust, noise, and structural vibrations, leading to enhanced safety and environmental stewardship.

Conclusion: The Future of Concrete Cutting

As sustainable practices and regulatory compliance continue to guide construction trends, precision concrete cutting is positioned as a foundational process in infrastructure and architectural development. Fusing innovative techniques, advanced machinery, and rigorous safety standards allows for cleaner, safer, and more ambitious construction projects. Adaptable professionals and forward-looking companies investing in technology and training will continue to drive progress, transforming challenges into new opportunities within the built environment.